There are various types of pliers available for specific functions. The pliers that are used in woodworking project are called carpenters pliers. Actually, it is known as carpenters pincers. It is one kind common and basic hand tools for carpenters. They use it to pull out nail or to hold wide range of object firmly. Normally it is made of steel alloys combination with other metals like vanadium or chromium. These metals improve strength of the pliers and prevent them from corrosion.

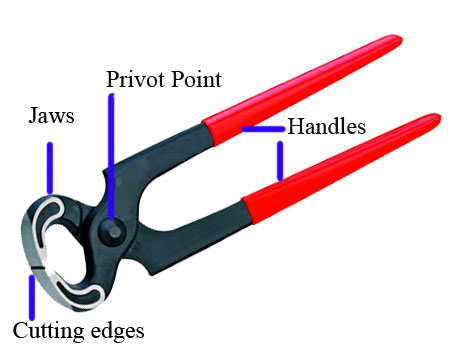

Parts of Carpenter pincers

The carpenter’s pincers have many parts such as jaw, cutting edge, pivot point and handles. Each of the parts has specific tasks. The functions of the parts are described as below:

Jaw

Carpenters pincers have broad range rounded jaws. It protects the wood during extracting nails or staples to damage. It also helps to pulling out the nails and staples.

Cutting edge

The cutting edge has beveled type and broad tip. It provides the pincers an extra cutting strength to grip when the carpenters want to cutting or pulling the nails. The edge of the good quality pincers will meet together without any gaps and provides plenty of cutting strength.

Pivot Point

Pivot point is the center point for moving the handle and jaws. Normally, it consists of a nut or screw. Some has two pivot points. The first pivot point acts as a lever on the second one, magnifying the force applied to the jaws for the same amount of effort.

Handles

The handles act as levers to force the jaws. Normally, the most part of the handle are covered with plastic or rubber for comfort and for good looking. The carpenter’s pincers consists of two handle. When the force applied on the handle, they moves in opposite directions, around a center pivot and comes together like scissors.

What are carpenters pliers used for?

The carpenters pincers are used for gripping and pull out nails or clevis pins from wood without damaging the wood work piece surface. It has wide rounded jaws; therefore it would not dig into the wood. It is also useful for repairing windows and doors, removing skirting boards and renovating furniture. Some pincers are design with hammerhead to striking the nails. Moreover, it is also used for cutting nails, wire or staples.

Difference between End cutting and carpenters pincers

The main difference between the End cutting and carpenters pincers are cutting edges, jaw size and handle length. The end cutting pincers have very sharp cutting edges compare to carpenters pincers. Therefore it can easily cut nails and bolts, so it is used for cutting while carpenter pincers are used for pulling nails. Most of the end cutting pincers sizes are 150mm to 200mm whereas the carpenters pincers can up to 300 mm. On the other hand the width of the head can be 20mm-30mm. The end cutting pincers may have return spring to reduce the effort for repetitive task. End cutting pincers, also known as end cutters, nippers or end cutting pliers.

Conclusion

Always choose right carpenters pliers for your woodwork, so that they fit well. You should not use the pincers for thicker objects that the sizes are projected. Never use them as a hammer. Otherwise they will be damage.